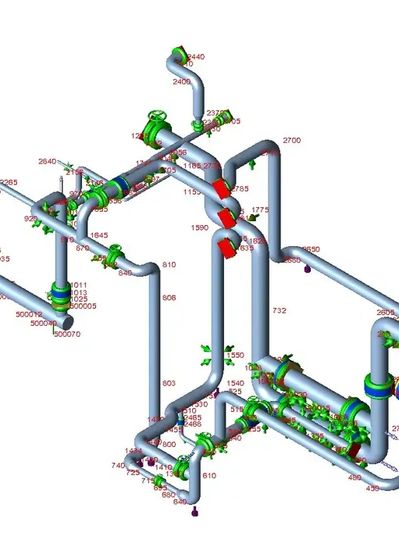

PIPING STRESS AND FLEXIBILITY ANALYSIS

✅ From field measurements to proven solutions — we engineer confidence into every line.

At PTG, we specialize in the analysis and optimization of piping systems to ensure safety, compliance, and long-term reliability.

Our piping stress and flexibility analysis service identifies how temperature changes, internal pressure, equipment loads, and support configurations affect your piping network.

By combining advanced modeling techniques with field-accurate data from LiDAR 3D scanning, we simulate real-world operating conditions — not idealized drawings — to provide engineering solutions that prevent costly failures and downtime.

Our expertise helps you detect and resolve issues such as excessive stress, displacement, nozzle overloads, vibration, misalignment, and support failures before they lead to leaks, fatigue cracking, or loss of containment.

PTG’s analytical approach ensures every piping system is compliant with ASME B31 codes and plant standards while maintaining flexibility, stability, and structural integrity.

What Our Analysis Can Do

- Evaluate thermal expansion, sustained, and occasional loads to prevent overstress or excessive movement

- Optimize pipe routing and support configuration to balance flexibility and restraint

- Verify equipment nozzle loads against allowable limits (pumps, compressors, exchangers, vessels)

- Identify and mitigate vibration or dynamic loading issues (flow-induced or acoustically driven)

- Assess displacement, anchor movement, and settlement impacts on connected systems

- Analyze expansion joints, springs, and snubbers for proper selection and load distribution

- Review hanger settings and load distribution to maintain stability during hot and cold operation

- Detect and correct misalignment and installation deviations using field scan data

- Provide code-compliant reports and recommendations for safe, efficient operation

Why It Matters

- Prevents costly downtime caused by leaks or fatigue failures

- Improves equipment life by reducing nozzle and support loads

- Ensures code compliance with ASME B31.1, B31.3, and applicable industry standards

- Supports safer operations through verified flexibility and stress limits

- Enhances accuracy by integrating as-built field conditions from 3D scans

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.