About PTG

Our Mission

At PTG, our mission is to deliver precise, data-driven piping engineering that bridges the gap between field reality and analytical accuracy.

We specialize exclusively in piping stress and flexibility analysis and high-precision LiDAR 3D laser scanning for industrial plants, refineries, and process facilities.

Our approach begins with measurement — using sub-millimeter 3D scans to capture true as-built conditions, including sagging, deflection, and misalignment. These point clouds feed directly into our CAESAR II stress models, ensuring that every analysis reflects the actual geometry and loading behavior of the system.

By combining engineering expertise with advanced digital capture, PTG helps clients prevent failures, optimize support configurations, and extend equipment life.

We are committed to accuracy, reliability, and practical solutions that enhance safety and performance across every project we deliver.

Our Vision

Our vision at PTG is to be a trusted partner and industry leader in precision piping engineering — setting the standard for stress and flexibility analysis and high-accuracy LiDAR 3D laser scanning. We aim to redefine how facilities approach reliability and integrity by transforming real-world field data into actionable engineering insight.

We see technology and collaboration as the foundation of smarter, safer plants. By combining practical field experience with advanced digital modeling, we enable clients to make informed decisions that reduce risk, prevent failure, and extend asset life.

Above all, our vision is to build lasting relationships with our clients through accuracy, responsiveness, and innovation — delivering engineering that makes a measurable impact across refineries, chemical plants, and industrial facilities throughout the region.

Our EXPERTISE

At PTG, we deliver precise and reliable engineering solutions focused on piping systems and field-accurate data capture. Our expertise combines real-world field experience with advanced analytical modeling to help clients improve safety, reliability, and performance across their facilities.

Piping Stress & Flexibility Analysis

Comprehensive evaluation of piping systems for sustained, thermal, and occasional load cases in accordance with ASME B31 and applicable codes. We assess support configurations, nozzle loads, and displacement limits to ensure safe operation and long-term reliability.

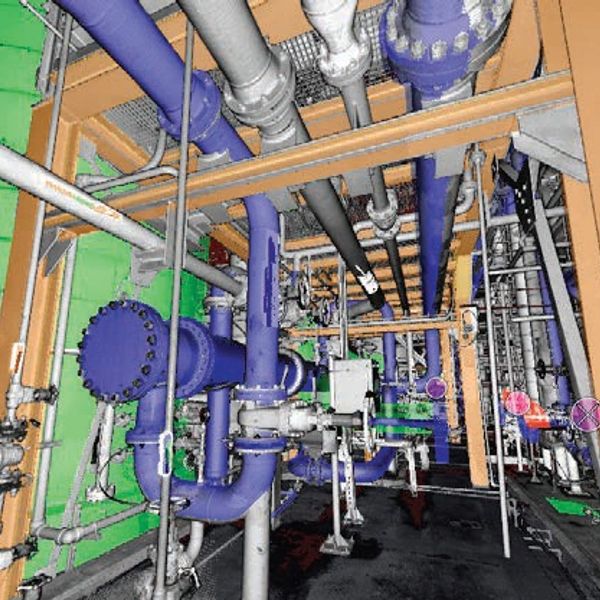

High-Precision LiDAR 3D Laser Scanning

Sub-millimeter LiDAR scanning captures true as-built geometry, including pipe sagging, deflection, and misalignment. Our scans integrate directly into analytical and design platforms, providing accurate input data for stress analysis, rerating, or modification projects.

Field-to-Model Integration

We bridge the gap between plant reality and engineering analysis—aligning 3D scan data with analytical models to eliminate guesswork and reduce field rework. This approach ensures that every recommendation reflects actual site conditions.

PTG Services

PIPING STRESS AND FLEXIBILITY ANALYSIS

We provide comprehensive piping system evaluations focused on safety, reliability, and long-term performance.

Our services include detailed stress and flexibility analysis, support and restraint design, and verification of piping integrity under thermal, sustained, and occasional load conditions.

Following industry standards such as ASME B31 and API, we help clients prevent overstress, reduce vibration issues, and ensure stable, efficient operation of critical systems.

HIGH-PRECISION LiDAR 3D LASER SCANNING

Our sub-millimeter LiDAR 3D scanning captures the true as-built condition of piping systems with exceptional accuracy.

This advanced technology identifies pipe sagging, deflection, elevation variance, and flange misalignment, providing a reliable digital foundation for engineering analysis and design.

By combining precise field data with analytical expertise, PTG helps clients eliminate guesswork, streamline maintenance planning, and improve project confidence through measurable accuracy.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.